The patented compactMASTER milling spindle is the guts and soul of the Turn & Mill models from DMG MORI. Its extremely-compact dimensions and its significant swivel assortment help optimal use in the working Room.

It is actually The perfect option for small spaces and confined working environments. That has a tool turret for 16 driven tools and yet another Y-axis, it might fulfil a variety of machining duties.

Robotics and automation enthusiasts can collaborate with CNC machining industry experts to design and generate custom components, force the boundaries of engineering opportunities, and drive innovation forward.

Privacy Overview This Internet site takes advantage of cookies in order that we will present you with the most beneficial user expertise attainable. Cookie facts is saved in the browser and performs capabilities such as recognising you when you return to our Web site and assisting our group to comprehend which sections of the website you find most attention-grabbing and useful.

Our educate lathes are developed with robust, secure, and wider bed way for optimum vibration absorption. The whole bed features superb structural rigidity. Dovetailed carriage and cross slide are hardened, high precision ground, coated with Turcite-B and scrape finished to be sure uniform surfaces.

H2o jet cutters hire intense water streams to precisely Lower by a variety of materials, including metals, plastics, glass, and stone. With the chance to Slash without heat, h2o jet cutters are significantly practical for materials that are delicate to high temperatures or need high precision. Industries for instance aerospace, architecture, and signage normally make use of drinking water jet cutting technology.

Automatic Production Lines: Improved automation and robotic integration will further more enhance automotive manufacturing processes, leading to higher throughput and reduced labor costs.

No matter whether you’re Doing work within a toolroom, a high-tech industry, or anyplace between, these machines offer you the features, specifications, and reliability necessary to make sure your jobs are Visit this page concluded for the highest standards of precision and quality.

Making use of Progress CNC’s multi-axis CNC machines enable for shorter lead times and bigger accuracy than most other machine outlets in the United States. Let us make the expenditure for yourself so you can obtain again to accomplishing Whatever you do ideal.

As we explore the breakthroughs in CNC lathe technology in the subsequent part, the evolution of such machines is usually a testomony on the industry’s ongoing commitment to excellence.

In summary, diving into high precision CNC lathes is like entering a realm in which the slightest variation matters. No matter whether you’re working with Kern, navigating the capabilities of 5-axis machines, or marveling in the precision of Swiss machines, keep in mind: On this planet, each and every micrometer counts.

TURNPWR was produced to satisfy the wants and needs of lathe machinists wherever manual and automated Procedure are both useful and necessary.

This capacity is priceless in industries that require rapid-paced innovation and solution development, like robotics and buyer electronics.

Solid sink EDM is a unique machining process that employs electrical discharge to get rid of material from conductive surfaces. This process is used for intricate and sensitive workpieces, which include those found in the aerospace and medical industries.

Spencer Elden Then & Now!

Spencer Elden Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Ross Bagley Then & Now!

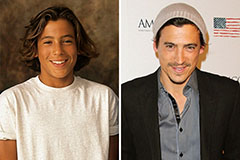

Ross Bagley Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!